There are many types of abrasive blasting applications each of which requires the use of different types of blasting materials referred to as blasting media.

Sandblasting stainless steel exhaust.

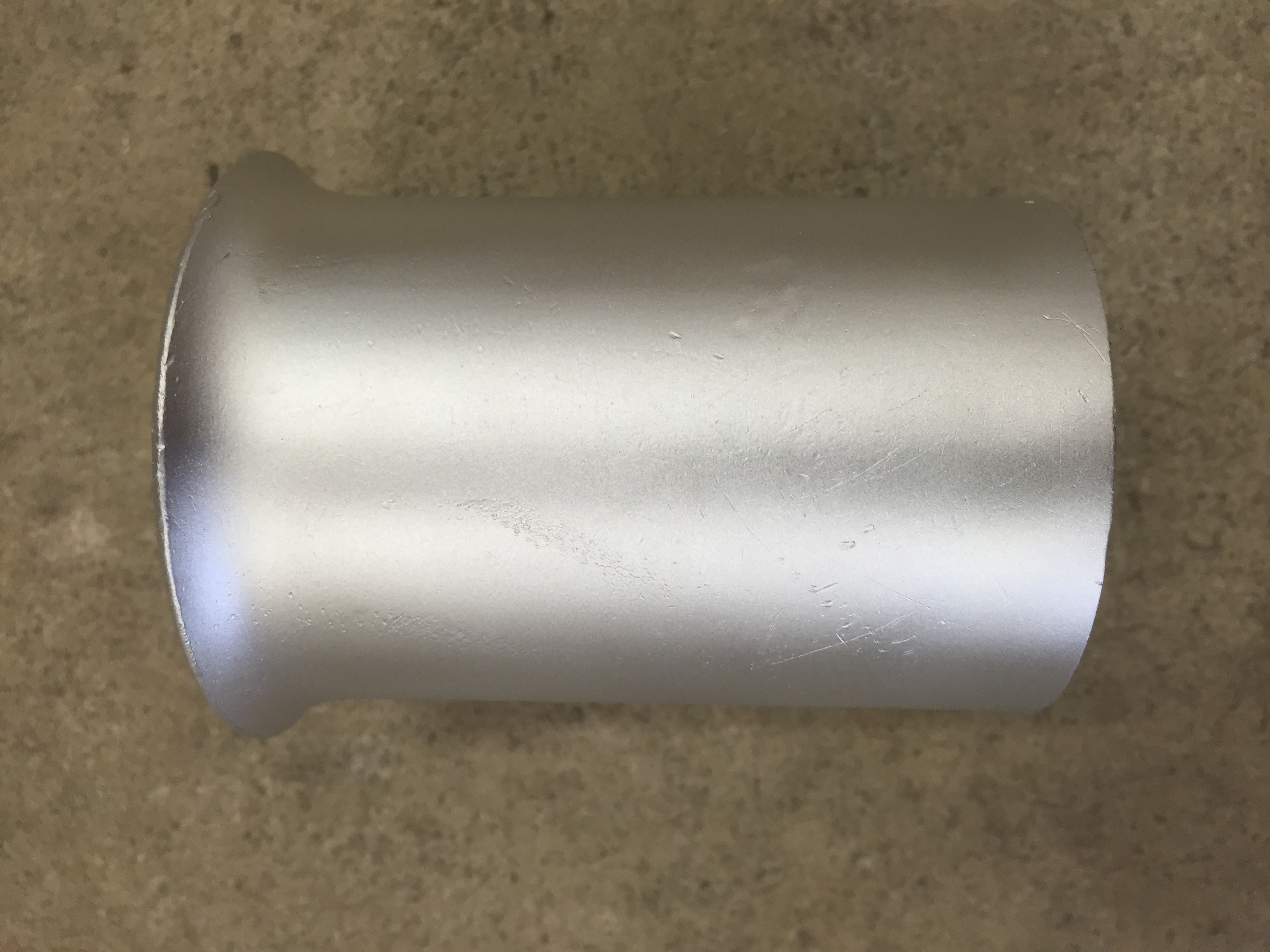

We have the capabilities to glass bead blast our stainless parts for a great finish that our customers our very happy with.

The post blasting stainless steel for a satin finish a guide appeared first on pittsburgh spray equipment company.

The sandblast material was an abrasive silica that would pulverize upon contact with the metal surface and create thousands of fine.

Either before or after fabrication.

However a customer has inquired into passivation and if the glass bead blast technique achieves the same result.

Dust collector captures exhaust from sandblasting operation.

Blasting can expose rust prone elements.

The role of blasting a lot it can remove the stainless steel tube castings forgings or after heat treatment the oxidation of the surface skin but also can remove.

Do a google search on passivating stainless.

These finishing methods can be used in the specialist finishing shop or under site conditions i e.

By choosing a blast media that is best suited to achieve a satin finish and understanding the settings and type of blasting to use you should be able to better achieve satin finishes when sandblasting stainless steel.

My company designs and builds equipment mainly for the food industry.

Can you sandblast stainless steel.

Sand blasting is the use of compressed air stream sprayed on quartz sand stainless steel pipe surface clean up or modification of the surface processing.

Be very wary of blasting stainless.

A steel fabrication facility had a dedicated bay for sandblasting and painting that required capturing and filtering smoke fumes and dust.

Abrasive blasting can serve many surface finishing purposes such as removing contaminants or previous coatings altering the shape and smoothing or roughening the surface.

The metal is passivated so that the rust free elements of the alloy nickel etc are at the surface.